1. STEP

Battery Development

For over 20 years, we have been researching the forefront of cell technology and production design. Each project starts with battery cell assembly; after ascertaining the customer’s requirements we look into the possibilities and employ the most innovative battery development methods. Even in this initial development stage we combine the best materials and technologies with precision craftmanship and customization.

- Advanced lithium-ion battery manufacturing technology

- Construction of design and mechanical aspects

- Conception and development of BMS including software

- Tests, approvals, standards, and directives

- Customized production design for battery manufacturing

- Advanced lithium-ion battery manufacturing technology

- Construction of design and mechanical aspects

- Conception and development of BMS including software

- Tests, approvals, standards, and directives

- Customized production design for battery manufacturing

2. STEP

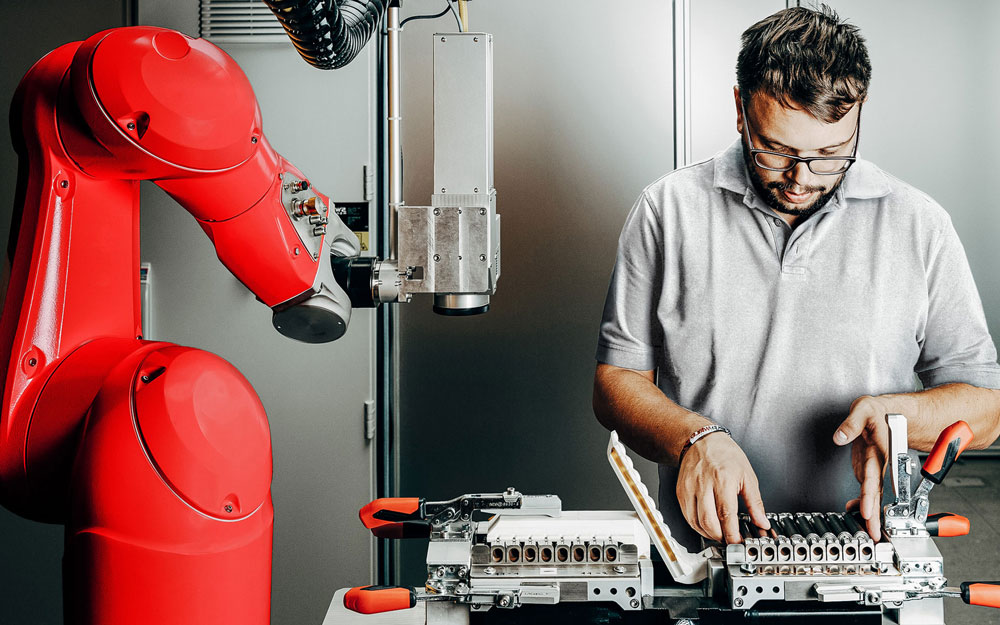

Battery Production

Our team of experts undertake battery development with the utmost drive and precision, with the highest quality and attention to detail throughout. The visions of individuals start to become reality, whether small runs or larger series. Resulting from this stage are working prototypes, combining specially-selected materials with intelligent processes.

- Rapid prototyping

- In-house prototype creation

- Production of both small and large series

- Customer-specific end-of-line (EOL) testing

- Rapid prototyping

- In-house prototype creation

- Production of both small and large series

- Customer-specific end-of-line (EOL) testing

3. STEP

Customer-Specific Solutions

Battery development is always a matter of customization. As each project has its own unique requirements and stipulations, individualization is a key concept for us. Instead of off-the-shelf batteries, our lithium-ion battery production is tailor-made and specially developed for each specific purpose. What begins life on pen and paper soon matures into a specific battery production solution. Each stage of battery development is adapted to your individual project and upscaled as required. Here is a small selection of the possibilities:

- Cell selection and long-term contracts for all the most common cell technologies

- Efficient coordination with manufacturers of electric motors and converters

- Support in selecting the right converter technology

- Batterieauslegung in Anbracht an Verbrauch und Reichweite

- Suitable charging infrastructure

- Flexible packaging options

- International transportation handling

- Waste and recycling management

- Cell selection and long-term contracts for all the most common cell technologies

- Efficient coordination with manufacturers of electric motors and converters

- Support in selecting the right converter technology

- Batterieauslegung in Anbracht an Verbrauch und Reichweite

- Suitable charging infrastructure

- Flexible packaging options

- International transportation handling

- Waste and recycling management

4. STEP

Service

Where others may see battery development as an end in itself, things go much further with us. Our service is defined by a long-term approach: long warranty periods, long-term spare parts provision, and extended after-sales assistance. Long after battery production, we ensure a responsible management of waste and recycling, as well as repairs and maintenance.

- After-sales service

- Extended warranty period

- Long-term spare parts provision

- Servicing and maintenance workshop

- Waste and recycling management

- After-sales service

- Extended warranty period

- Long-term spare parts provision

- Servicing and maintenance workshop

- Waste and recycling management