- Servus ARCs and vehicle control

should remain the same - Existing chargers should remain usable

(despite a different cell chemistry) - Mechanical casing with simple insertion mechanism

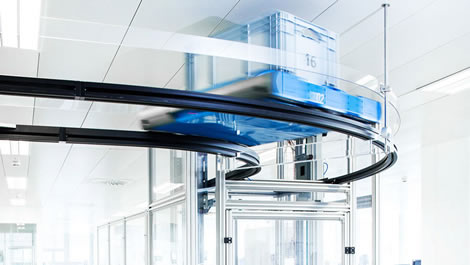

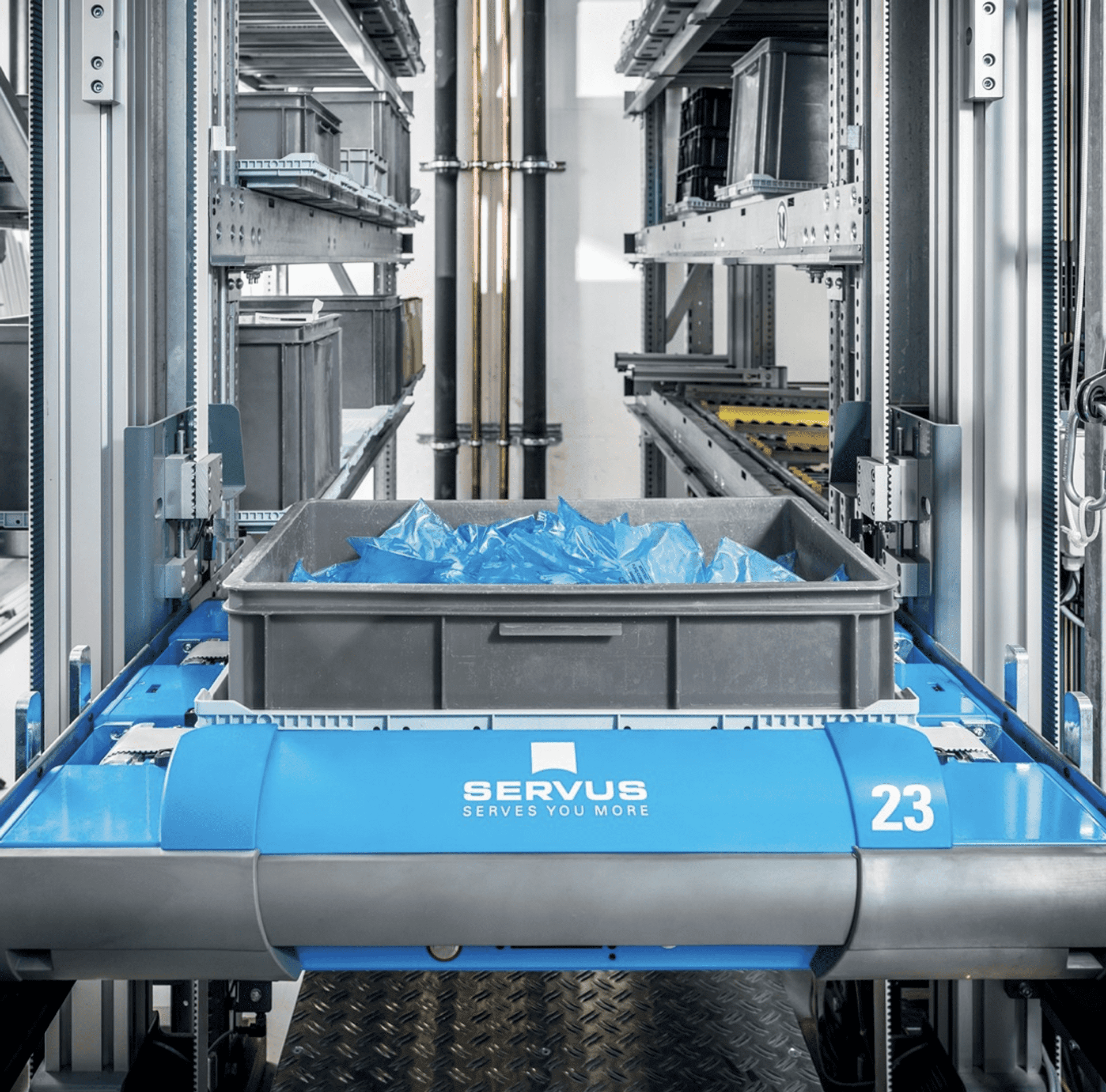

ARCs (Autonomous Robotic Carriers) by Servus Intralogistics are small moving units in warehouse systems and can now be found across storage and production facilities in various companies. These autonomous swarm robots adapt to whatever they are needed for, and help save time, money, and effort. Simply put, they supply picking stations and production lines with materials. Thanks to their decentralized nature, potential failures in the warehouse system are virtually eliminated.

The inherent flexibility and agility of small transport systems is made possible by intelligent robotic technology, but this in turn banks on a reliable energy supply. Charging in 6-8 seconds several hundred times a day, a lot is asked of this battery pack and its life span is stretched to the limit. Servus Intralogistics encountered problems with their old battery packs, leading them to contact e.battery systems. The possible optimizations were manifold, but the task was clear: to develop an intelligent Battery Management System (BMS) to replace existing battery technology while fulfilling complex prerequisites:

The inherent flexibility and agility of small transport systems is made possible by intelligent robotic technology, but this in turn banks on a reliable energy supply. Charging in 6-8 seconds several hundred times a day, a lot is asked of this battery pack and its life span is stretched to the limit. Servus Intralogistics encountered problems with their old battery packs, leading them to contact e.battery systems. The possible optimizations were manifold, but the task was clear: to develop an intelligent Battery Management System (BMS) to replace existing battery technology while fulfilling complex prerequisites:

- Accurate calculation of State of Health (capacity)

- Accurate calculation of State of Charge

to within 0.5% (charging state) - Intelligent control of battery monitors

and protective circuits

- Updates via HP battery charger

should be possible - Bidirectional communication

between battery and HP battery charger

(for updates und checks)